As the demand for renewable energy sources grows, wind power has emerged as a prominent solution. Wind turbines harness the power of wind to generate electricity, and their efficient operation relies on robust and reliable components. Among these components, FAG Bearings play a crucial role in supporting the rotating parts of wind turbines. This article explores the significance of FAG Bearings as key components in wind turbine technology, highlighting their design features, benefits, and contributions to the success of wind power generation.

Load-Carrying Capacity:

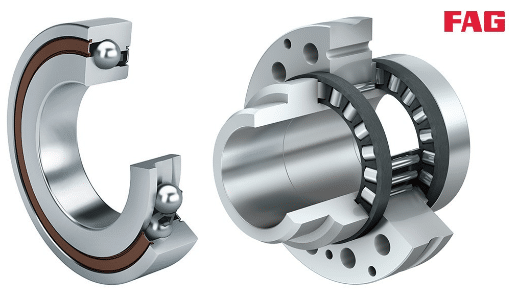

Wind turbines operate in demanding conditions, with varying wind speeds and dynamic loads. FAG Bearings are specifically designed to handle heavy loads encountered in wind turbine applications. Their optimized internal geometry, high-quality materials, and advanced manufacturing processes enable them to withstand the substantial forces generated by wind turbine rotor blades. The superior load-carrying capacity of FAG Bearings ensures the safe and reliable operation of wind turbines.

Durability and Longevity:

Wind turbines are subjected to continuous rotation and exposure to harsh environmental conditions, including temperature fluctuations, moisture, and contaminants. FAG Bearings are engineered to withstand these challenging conditions and maintain their performance over an extended period. Their robust construction, advanced sealing mechanisms, and effective lubrication systems contribute to enhanced durability and extended service life, reducing maintenance requirements and downtime.

Friction Reduction:

Efficiency is a crucial factor in wind turbine operation. FAG Bearings are designed to minimize friction and reduce energy losses. The use of high-quality materials, precision manufacturing techniques, and optimized internal geometries results in low friction coefficients, enabling efficient power transmission and maximizing energy conversion. Reduced friction also contributes to lower operating temperatures, extending the life of the bearings and other critical components.

Reliability and Safety:

Reliability and safety are paramount in wind turbine applications. FAG Bearings undergo rigorous testing and quality control processes to ensure consistent performance and adherence to industry standards. The reliability of FAG Bearings minimizes the risk of failures, preventing costly downtime and potential safety hazards. Their ability to withstand extreme conditions, fatigue resistance, and fault-tolerant designs make them a trusted choice for wind turbine manufacturers and operators.

Maintenance and Serviceability:

FAG Bearings are designed for ease of maintenance and serviceability in wind turbines. They incorporate features such as integrated sensors for condition monitoring, allowing early detection of potential issues and facilitating proactive maintenance. The availability of spare parts, technical support, and expertise from FAG Bearings ensures efficient maintenance and swift replacement when required, minimizing downtime and optimizing turbine performance.

Application-Specific Solutions:

FAG Bearings offer application-specific solutions tailored to the unique requirements of wind turbine technology. They collaborate closely with wind turbine manufacturers and operators to understand their specific challenges and develop customized bearing solutions. Whether it’s a large-scale onshore wind farm or an offshore installation, FAG Bearings provide optimized solutions that maximize performance, reliability, and efficiency, contributing to the overall success of wind power generation.

Continuous Innovation:

FAG Bearings is committed to continuous innovation and research, driving advancements in wind turbine bearing technology. They invest in research and development to improve bearing designs, materials, and manufacturing processes. By staying at the forefront of technological advancements, FAG Bearings enables the wind power industry to benefit from the latest innovations, improve efficiency, and optimize power generation.

Environmental Benefits:

Wind power is a clean and sustainable energy source, and FAG Bearings contribute to its environmental benefits. Through their high efficiency, reduced friction, and extended service life, FAG Bearings help maximize energy conversion and minimize energy losses. This not only enhances the overall performance of wind turbines but also reduces the environmental impact by maximizing the utilization of renewable energy resources.

Conclusion:

FAG Bearings play a pivotal role as key components in wind turbine technology. With their superior load-carrying capacity, durability, friction reduction, reliability, and application-specific solutions, FAG Bearings ensure the safe, efficient, and sustainable operation of wind turbines. As the wind power industry continues to grow, FAG Bearings will continue to innovate and provide advanced bearing solutions that meet the evolving demands of wind turbine technology, further advancing the development of clean and renewable energy sources.

We support more information about Bearings. you can visit https://cmtgbearing.com. or email us info@cmtgbearing.com.